- Home

- All Posts

- Battery Material

- Bipolar Plate

- Composite Bipolar Plate & Composite Integrated Electrode

Blog

Composite Bipolar Plate & Composite Integrated Electrode

Composite conductive plastic bipolar plate

Flow battery (vanadium redox flow battery/zinc bromine flow battery, etc.) is mainly composed of electrolyte tank, electric stack and water pump. The electrode material and ion exchange membrane are important parts of stack. For instance, vanadium battery is most widely used in energy storage market, its electrode material consists of graphite bipolar plate and carbon felt(graphite felt). The stack structure of vanadium battery is composed of graphite bipolar plate, carbon/graphite felt and proton exchange membrane, which are stacked and assembled layer by layer. The assembled battery stack is fastened by bolts around the stack.

Because graphite bipolar plate material is very brittle, the carbon/graphite felt will extrude the graphite bipolar plate during the assembly process, it may cause small deformation. It’s easy to produce fine cracks if the stress is not released, building pressure with air inside the stack can easily detect potential leak problem. Moreover, during the operation of battery stack, the graphite electrode plate is easily peeled off under the long-term pressure scouring of the electrolyte, and the graphite powder falling from graphite plate will cause siltation and blockage.

The composite conductive plastic bipolar plate for VRFB offered by Nanjing xunenghanyuan new materials Co., Ltd.(XNHY), is a composite material made of polyethylene(PP or PE) as an adhesive and carbon based conductive materials. The plastic electrode has properties of good flexibility, anti twist, high tensile strength, corrosion resistance and no peeling phenomenon. The electric stack assembled with conductive plastic bipolar plates have been verified in pressure maintaining and gas insufflation test, proof by facts, there was no problem of pressure and air leakage.

Composite carbon felt electrode

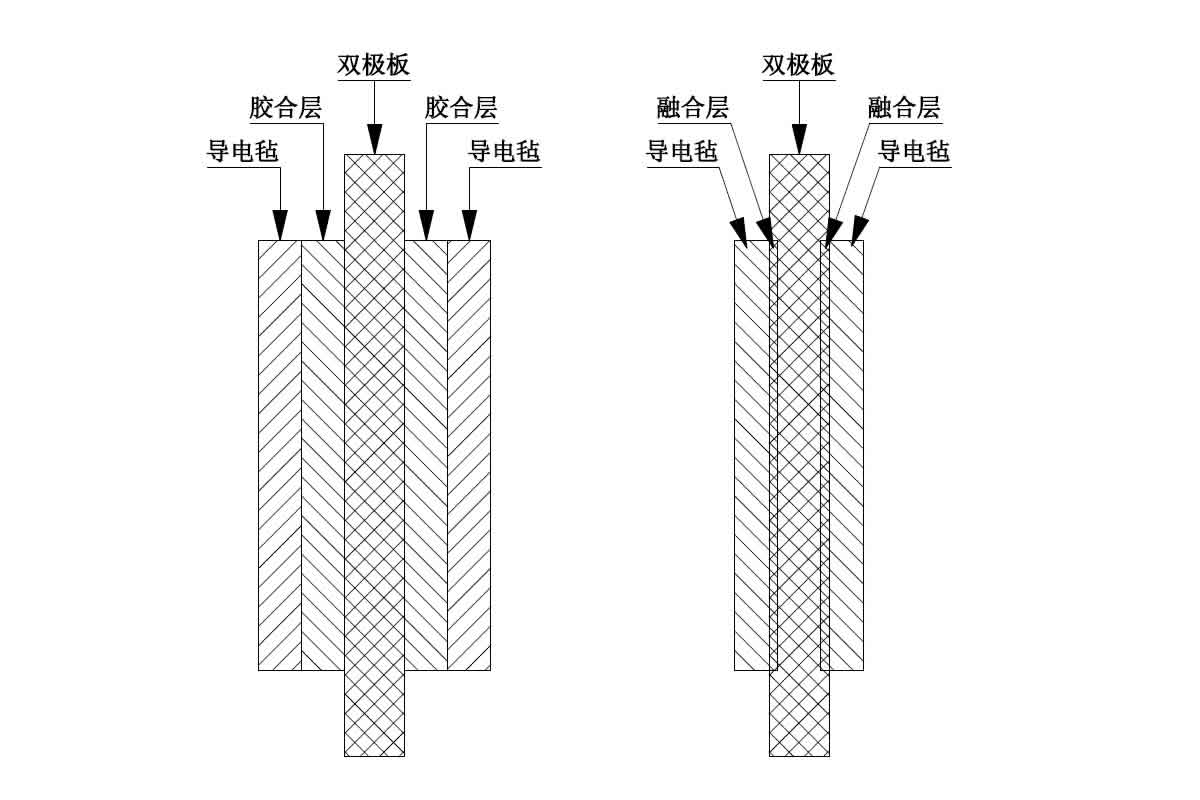

During the assembly process of flow battery, whether it is composition based on graphite bipolar plate and graphite/carbon felt, or composition based on composite conductive bipolar plate and carbon felt/graphite felt, there will generate contact resistance between conductive felt and bipolar plate. The contact resistance in battery stack is the key factor that deteriorates battery performance and affects the energy efficiency of the battery, also affects the performance consistency between each group of series battery cells in assembly. In order to solve the problem of contact resistance, some manufacturers use adhesive to bond the carbon felt and the bipolar plate together, However, the conductivity of the electrode become poor.

This contradictory phenomenon provides important benefits to conductive plastic bipolar plate. Composite integrated carbon felt electrode offered by XNHY uses a special technical process to fuse the plastic conductive bipolar plate and carbon felt, and the graphite felt is perfectly embedded in the plastic polar plate. They combine with each other, which greatly improve the conductivity and battery efficiency. Comparing with adhesive integrated electrode, the advantages of composite carbon felt electrode are mainly reflected in:

1) The conductive felt is thinly embedded in the bipolar plate, which doesn’t occupy the pores of the conductive felt, and the assembly compression space of the conductive felt is not affected.

2)Use special fusion process to make conductive felt and composite bipolar plate combined perfectly, and the joint surface is flat without dead angle.

3)There will be no peeling or degumming issues which frequently take place on adhesive integrated electrode.

4)Found by violent break of conductive felt, The joint surface can keep intact and no peeling phenomenon.

In summary, composite conductive plastic bipolar plates are most widely used in Vanadium redox flow battery due to its simple preparation process and low cost. However, how to further reduce the resistivity of the material while maintaining the strength, which require study. The composite carbon felt electrode can reduce the contact resistance between the electrode and the bipolar plate, keep basic pore structure of the electrode unchanged, and improve the distribution of electrolyte in the electrode, which has become the key of current research.

About Mr. Zhou

Search

Recent Posts

-

Manufacturing Process of Ca... 11/28/2024

-

Application of Flexible Gra... 05/14/2024

-

PEM Water Electrolysis for ... 04/12/2024

-

Application of Bipolar Memb... 01/09/2024

-

Membrane Electrode Assembly... 11/27/2023

Categories

- All Posts (24)

- Flow Battery (11)

- Battery Material (20)

- Bipolar Plate (13)

- Membrane (3)

- Felt Electrode (1)

- MEA (3)

- Fuel Cell (5)

Contact Info.

Recent Post

-

Manufacturing Process of Ca... 11/28/2024

-

Application of Flexible Gra... 05/14/2024

-

PEM Water Electrolysis for ... 04/12/2024

-

Application of Bipolar Memb... 01/09/2024

-

Membrane Electrode Assembly... 11/27/2023